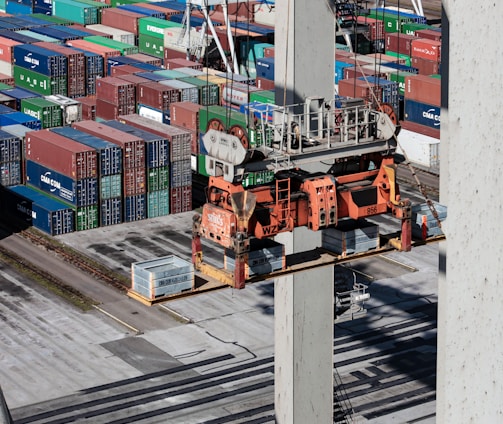

We offer efficient import services for iron scrap materials from different countries to India

Our Services

Excellent service and quality materials. Highly recommended.

Customer Reviews

Reliable and professional. Always deliver on time.

About Us

German Metals Private Limited is a top iron scrap importer in India, with global supplier connections guaranteeing superior material quality. Our team is dedicated to efficient and dependable import services